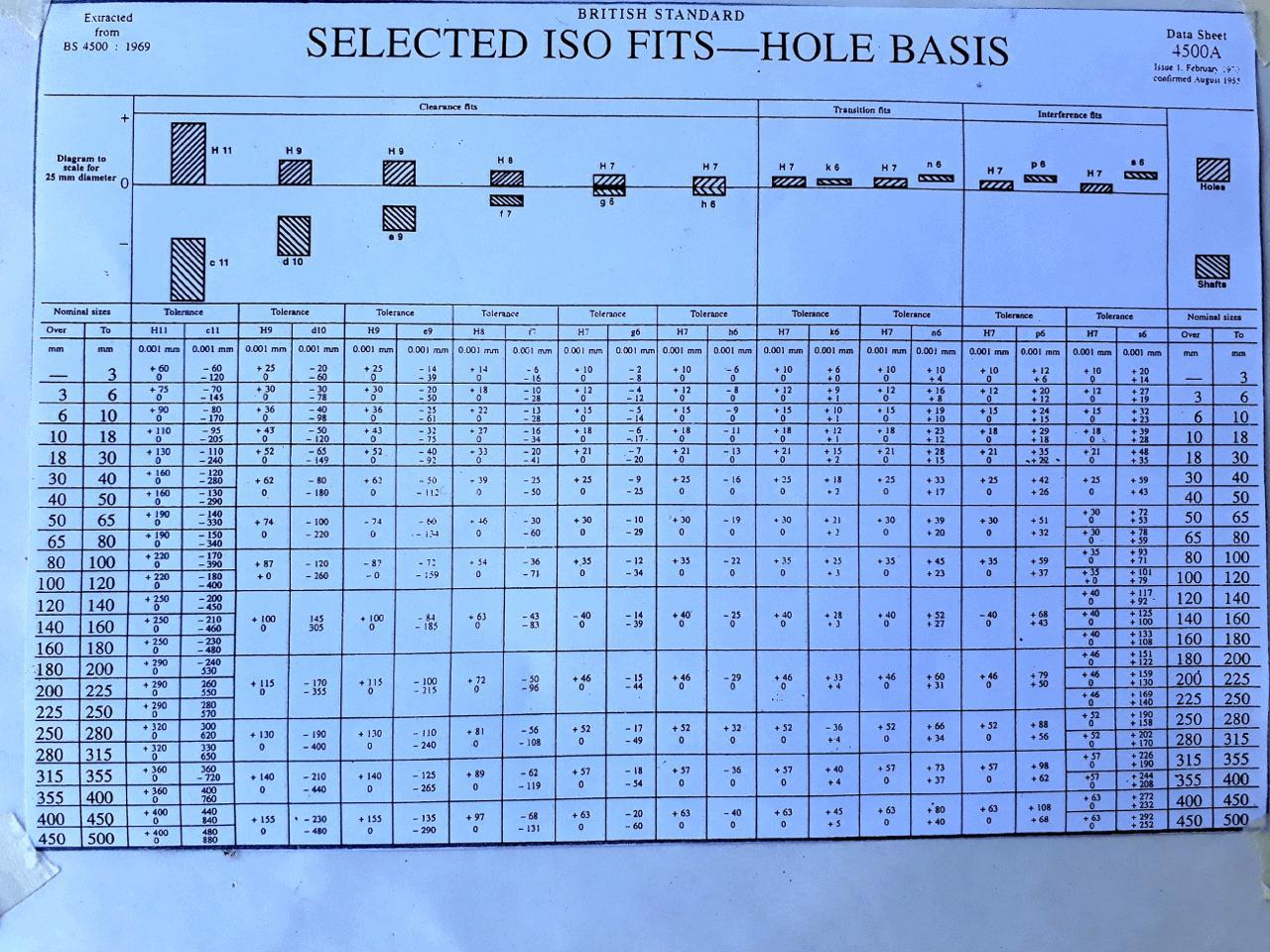

Imagine trying to draw a shadowgraph to inspect the R3. Parker Steel Company 1625 Indian Wood Circle Maumee, Ohio 43537 U.S.A. ISO Hole Tolerance,ISO Hole Tolerances,Hole Tolerance,ISO 2. Tolerancing points in space that cannot be. IS0 286-1 (2010) Geometrical product specifications (GPS) - ISO code system for tolerances on linear sizes - Part 1: Basis of tolerances, deviations. ISO Tolerances for Holes (ISO 286-2) ISO Tolerances for Holes (ISO 286-2) Nominal hole sizes (mm) over 3. It should be clearly understood, however, that the tolerances and deviations given in ISO 286-2 equally apply to workpieces of other than circular sections. Iso 2768 Hole Tolerance Zones Undesirable tolerance accumulation. For simplicity, and also because of the importance of cylindrical workpieces of circular section, only these are referred to explicitly. The tolerances work in such a way that for a hole H7 means that the hole should be made slightly larger than the base dimension (in this case for an ISO fit 10+0.0150, meaning that it may be up to 0.015 mm larger than the base dimension, and 0 mm smaller). The ISO system for tolerances on linear size provides a system of tolerances and deviations suitable for features of the following types: H7/h6 is a very common standard tolerance which gives a tight fit. ISO 286-2 covers values for the upper limit deviations e U, hole (for holes) and e U, shaft (for shafts) and the lower limit deviations e L, hole (for holes) and e L, shaft (for shafts). ISO 286-2:2010 gives values of the limit deviations for commonly used tolerance classes for holes and shafts calculated from the tables given in ISO 286‑1. Stephenie meyer midnight sun italiano pdf. For new designs only the general tolerance according to DIN ISO 2768-1. ISO 2768 – m or general tolerance ISO 2768 – m.

0 kommentar(er)

0 kommentar(er)